Ingersoll-Rand helped push the oil and gas industry into the 21st century and is still one of the most reliable and popular engines today. Let Reynolds-French help you to extend and improve the working life of your Ingersoll-Rand engines into the next century.

Even dependable engines/compressors like Ingersoll-Rand equipment can be run long and hard enough to require repairs and machining to their frames. This section shows some of the more common areas where problems arise, and the solutions to these problems routinely made by REYNOLDS-FRENCH.

Types of Repairs

Compressor Crosshead Bed Section

Misalignment of compressors or loose compressor cylinder bolts will cause damage to compressor flange, compressor cylinder bolt holes, and support webbing.

KVS crosshead bed section with catastophic rod damage. Damaged area removed by perforating and milling. Some steel fabrications installed (all repairs accomplished on location).

Same KVS crosshead bed section linebored, flange faced, and spigot fit machined.

KVS with damage to compressor crosshead bed section flange with cracks out of stud holes into inspection window, pulled and stripped threads in stud holes, and badly fretted flange.

Similar KVS crosshead bed section repaired on location by installing special steel fabrications at inspection window and around flange with special bolting and bushings. Crosshead bed section flange faced and spigot fit machined.

Upper Main Frame

The upper frame of many INGERSOLL-RAND engines have a common design. Cracks found coming from under the power cylinders are a direct result of damage in the crankcase. REYNOLDS-FRENCH has discovered that, over a period of years, the tie bolts loose their torque. When this happens, the upper frame starts moving and cracks start out of the nut pockets and extend to the outside, center, and crown of the upper frame and splitline flanges fret.

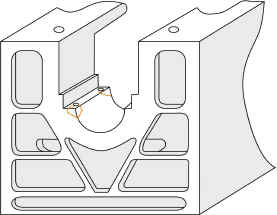

KVS/KVG upper main frame crosss-sectional drawing showing areas where breakage normally occurs (orange lines).

KVS/KVG upper main frame with damage to structural webs out of nut pockets. Note: Special bolting and extended thru bolts with acorn nuts ( see circled areas) to take power cylinder loading.

Anchor Bolt Rail

Often the anchor bolts are overlooked when it comes to regular maintenance. Over a period of time these bolts will lose their torque and the engine will begin to move and even “jump up and down”. This will result in a broken anchor bolt lug, fretting of the bottom rail, and in some extreme cases, damaging the grout.

KVG with crack across rail at anchor bolt tie-down lug area. Crack is metal stitched to ensure oil seal.

Same KVG with special steel fabrications bolted to frame and welded steel-to-steel to reinforce and distribute anchor bolt loading above the crack. Repairs accomplished and completed on location.

Crosshead Bed Section and Flange

Often unpredictable operating conditions and misalignment can lead to compressor rod failure. When a compressor rod breaks, the result can be minor, or as you can see by these photos, it can be a catastrophic failure

REYNOLDS-FRENCH has extensive experience in repairing the damaged sections by rebuilding the affected frame areas and machining them back to standard.

In the photos below, the top of the crosshead bed section was gone, along with the side of the compressor flange. Due to how the casting was broken, a steel fabrication was the most expedient procedure to get the engine back into service.

SVG with crosshead bed section rod damage. Damaged areas removed by perforating; steel fabrications bolted to parent material.

SVG with structural steel extending from back of crosshead bed section to the front, then welded steel-to-steel

Fabricated compressor flange is lined up with boring bar and bolted to cast iron parent material of crosshead bed section, then welded to structural steel as shown in photo. With all repairs completed, the flange is faced, spigot fit machined, and crosshead bed section slides linebored.

Upper and Lower Main Frame

This particular SVG engine is equipped with a bob-weight that runs in a crosshead bed section, similar to a compressor crosshead bed section. Should the bolts break that hold the bob-weight to the rod, damage will occur similar to the next three photos.

SVG compressor frame with upper frame damage resulting from a broken bob-weight. Damaged area machined to accept steel fabrications.

Special steel fabrications installed and welded steel-to-steel, then locked and metal stitched to ensure oil seal. The deck is machined with a portable mill, the power cylinder stud holes and splitline rail bolt holes are laid out and drilled back to O.E.M. specifications

SVG bob-weight flange on lower frame damaged from a broken bob-weight. View is looking down at the lower base splitline.

The lower frame, in these photos, sustained severe damage as well as the upper. The damage to the lower frame extends from the exterior wall to the interior support walls of the main bearing saddle. The crosshead bed section flange was knocked out along with a section of the split rail. REYNOLDS-FRENCH removed this section and installed steel fabrications to rebuild the side of the frame. All of the upper and lower frame repairs were accomplished on location.

Damaged sections removed and steel fabrications bolted into place in which new steel flange fabrications will be welded

After flange is welded, the steel fabrication is locked and metal stitched to parent material ensuring oil seal, the boring bar is installed, and flange is faced. Stud holes are laid out and drilled to O.E.M. specifications.

Main Bearing Cap Landing

When an engine is operating and the main bearing cap studs are loose, cracks will start out of bearing cap stud holes, fretting of the bearing cap landing can occur and, possibly, the engine will suffer crankshaft failure. This is not only time consuming, but expensive to repair. The engine must be dismantled and the crankshaft removed to perform the repair. Again, REYNOLDS-FRENCH can perform these repairs on location.

Damaged area is removed

with our portable milling machine.

New blocks are machined, fitted, and bolted in place. Bearing cap studs are extended, bearing caps installed, main bearing saddle is bored back to O.E.M. specifications.

KVS-412 upper and lower frames completely machined to O.E.M. specifications – splitlines and compressor flanges, key-ways, power cylinder and bearing cap landings,bearing cap jaw fit, bottom rail, compressor crosshead bed section and linebored