Types of Repairs

LS-8 Repaired on Site

Engine has damage on engine base and center frame.

Base repaired on site using steel fabrication and metal locks

Another engine returned to service by REYNOLDS-FRENCH repair methods

What’s New in Major Casting Repair

REYNOLDS-FRENCH “know-how” saved this block. A new cast section was used to replace the damaged bed section and, once again, an engine was put back into service through the experience and expertise of REYNOLDS-FRENCH.

THE PROBLEM:

LSV-16 with major damage on upper and lower frame

1

Two Damaged Main Bearing Saddles Removed

2

New Casting Installed & Locked into Place

3

Line Boring After New Saddles were Installed

4

Job Completed!

5

Can you see where this unit was repaired?

Co-Gen LSVB-20 Restored on Site

LSVB-20 required the following:

- Crankshaft straightened

- Crankpin turned

- Casting Repaired

- Field machine work

- Upper and lower liner fits restored

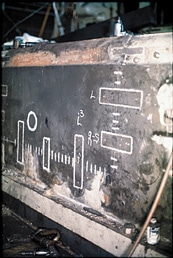

Left hand side of engine showing damage to base and center frame.

Inside view of crankshaft damage

Crankshaft straightened, crankpin turned, counter weight landings machined and counterweight studs replaced.

Area being repaired with steel fabrication and metal locks

Job completed making this another engine returned to service by REYNOLDS-FRENCH!

Replacing Damaged Main Bearing Saddles on LSV in Hawaii

- Broken main bearing saddle removed.

- Broken main bearing saddles removed and pattern made.

- New castings premachined and shipped to site.

- Casting installed. Machine finished to OEM specs

Broken main bearing saddle removed

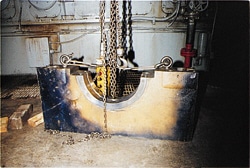

Base being made ready

for replacement casting

One of two new cast saddles set in place.

New saddles being line bored

Saddles in place and unit ready for reassembly

Flywheel Flanges Turned On Site

OEM specs maintained in the field by use of portable machine tools and Reynolds-French expertise.

Following are a few of our on-site machine services:

- Portable Milling of Decks & Flanges

- Line boring

- Crankpin turning

- Crankshaft Straightening

- Liner Fits Reclaimed

Flywheel flanges machined on site.

Boring upper liner fits

Crankpin turning, straightening and polishing on site

Block erosion and cylinder liner landing—repair machined and stainless steel inserts installed